Productos

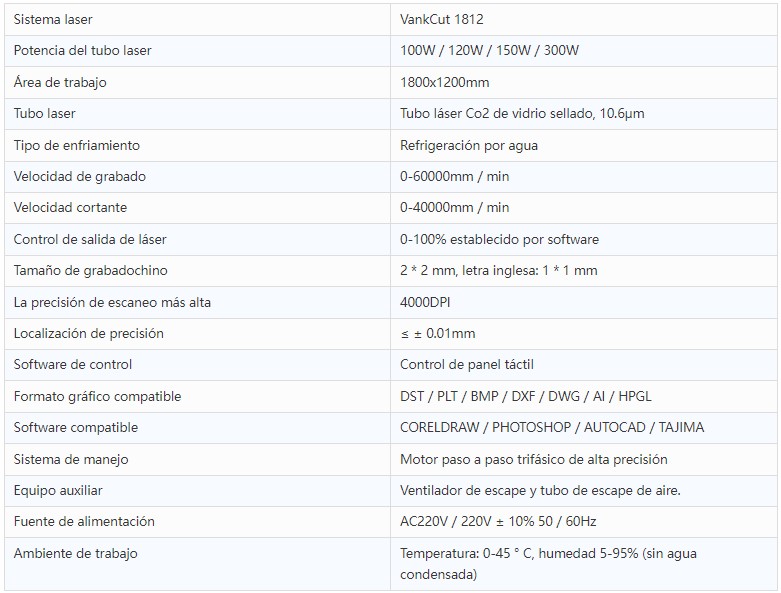

VankCut-1812 2 Head CO2 Laser Cutting Machine

Applicable materials

Wood, bamboo, jade, marble, organic glass, crystal, plastic, clothing, paper, leather, rubber, ceramics, glass and other non-metal materials.

Applicable Industries

Advertising, handicrafts, leather, toys, clothing, models, upholstery, computerized embroidery and cutting, paper and packaging industry.

Description

Laser Engraving and Cutting offers a large number of advantages to its users:

• Laser Engraving and Cutting allows great control over beam intensity, length and heat output.

• Laser Engraving and Cutting uses an extremely low level of energy consumption, generally around 10Kw compared to the 50Kw used by other processes.

• Laser Engraving and Cutting can work with a wide range of materials.

• Laser Engraving and Cutting is a non-contact process, which means that the laser beam itself never touches the material you are working with.

• This reduces heat damage to the surrounding area, increasing productivity by decreasing downtime and repair costs.

• Laser Engraving and Cutting Machines have very low maintenance costs and easy handling for individuals.

• Laser Engraving and Cutting offers precise cuts with fine finishes.

• Laser etch cutting can quickly switch between multiple applications and configurations, reducing wasted time and the need for multiples.

• With the above advantages, it’s easy to see why laser cutting is becoming so widely used.